Surface Preparation

Manufacturers formulate polyurea with some remarkable physical properties. These include enhanced adhesion. However, as mentioned before, there is rarely a successful polyurea application that does not include proper surface preparation and testing. This may seem like common sense, but some contractors attempt to cut corners on the prep work. Ultimately, projects typically suffer as a result.

Always follow proper surface preparation procedures and techniques. Additionally, we strongly recommended the use of primers in most applications. Consult the material supplier for the best compatible system/primer combination for each particular substrate. This is important because they may vary widely based on the conditions. Our contractors are familiar with the best combinations of primers and base/top coats for nearly every application.

Concrete Preparation

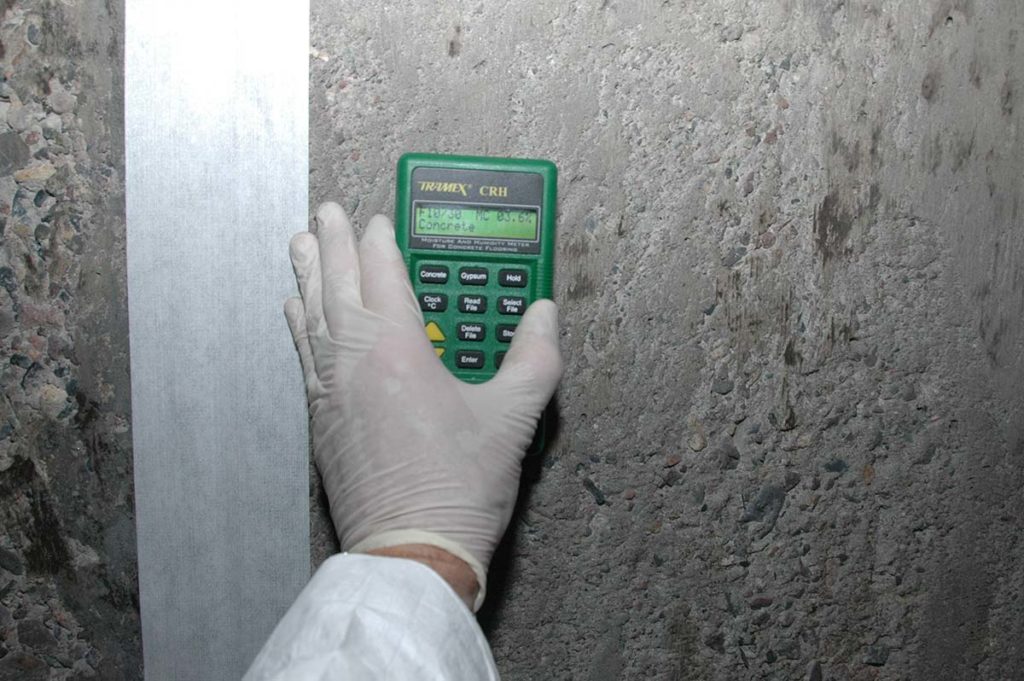

Concrete should cure a minimum of 28 days at 70° F (21°C). Hydration still continues even afterward, so the longer you wait, the better. Check the moisture content and vapor transmission for the concrete. Above all, try to ensure the concrete is fully cured. Finally, check that adequate surface conditions exist and that proper system adhesion can be achieved.

Concrete systems often require vapor barriers or other means of waterproofing to prevent water intrusion, which can ultimately lead to delamination and failure of the coating system. Remove all grease compounds and other foreign matter on the surface. Sandblasting, shot blasting, mechanical scarification or suitable chemical means will work for this process. Use these removal methods, along with controlled standards as provided by PDA, SSPC, NACE, and ICRI to clean and decontaminate the concrete surface.

Rout and fill racks in the concrete with an appropriate compatible material to the primer system. Fill any bug holes or pin holes in the same manner. Grind any sharp or rough surfaces to avoid protrusions. Finally, prepare the concrete surface with a grip enhancing profile to aid in proper adhesion of the primer and polyurea system.

Metal Preparation

Steel and metal surfaces must also be free from rust, salts, dirt and any other contaminants. Any welds should be free of voids and spurs and sharp protrusions, and should be ground smooth. Be sure to test the surface conditions prior to application of the primer and polyurea system.

Your protective coatings specialists.

Polyurea Systems

12461 Creekside Drive

Largo, FL 33773